The time has come:

Dear customer, let us inform you about

our latest 400 KW DC/DC converter in SiC

(silicon carbide) technology, which is characterized by the

smallest possible design with the highest possible efficiency. On request we lend devices to potential buyer for testing.

We have supplemented our portfolio in

the high-performance range with regenerative power factor correction

(PFC) modules, which also have a very high power density and

excellent performance. The PFC modules are regenerative and have

freely programmable phase angles, so they can also be used as phase

shifters.

We see ourselves as an OEM partner, for

example of electrical energy storage or hydrogen electrolyser

manufacturers. Our modules can be bundled into systems of several

megawatts. Our engineers and programmers have created their own

controls for this purpose. We achieve our high power density through

the consistent use of water cooling. Since the recoolers are usually

made of copper material, we also only use pure copper for the heat

exchangers in our new high-performance products. In the case of the

mechanical components, as in the electronics area, we can implement

everything because, in addition to the electronics, we also have our

own mechanical production with CNC machines.

We have been a recognized manufacturer

of power sources for discharge lamps for UV radiation generation and

pump lamps for laser technology for over 30 years and supply

applications in industry and medicine. Our technological background

has constantly evolved and our quality and production monitoring has

constantly grown with the requirements of medical technology. The

challenge of delivering technical feasibility with an optimal

price-performance ratio has always been our motivation.

Our 400 kW modules were created with

support from the Bavarian Energy Research Program of the Bavarian

State Ministry for Economic Affairs, Regional Development and Energy

with our own development team of engineers and technicians based on

our basic skills.

We have worked with SiC parts since the

first SiC components were available for industrial users, i.e. in

mid-2012. Among other things, laser current sources with a pulse

power of up to 900 kW were realized.

In addition to pure circuit

development, we also ensure cost-effective manufacturability through

the combination of automated production steps and monitored and

documented manual processes. To this end, a few years ago we set up

our business area for worker guidance systems, Computer Aided Works.

We see ourselves as well positioned as

an OEM supplier for "power at the highest level" because we

have combined electronics, mechanics and IT skills in-house.

Since 2020, iie GmbH & Co. KG has been a partner in the Hydrogen Alliance of Bavaria.

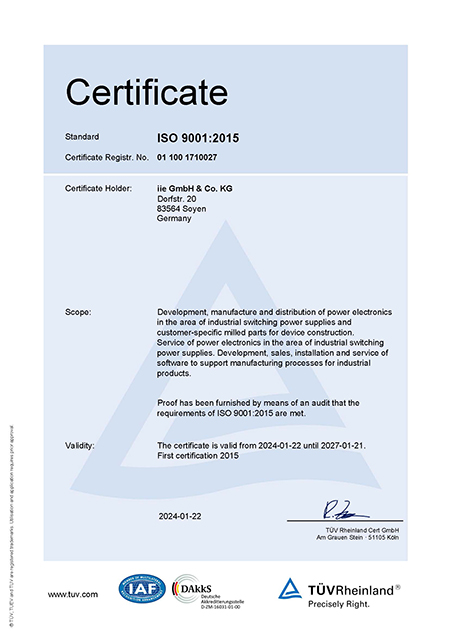

The iie GmbH & Co.KG is a certified development and production company.

For a full view of the files, please click on the following links:

- Zertifizierung_iie_01 100 1710027